Flash Point on petroleum products, gas oils, fuel oils, lubrificants, biodiesel. Suitable for flash point detection on different substances, waste materials, solvents…

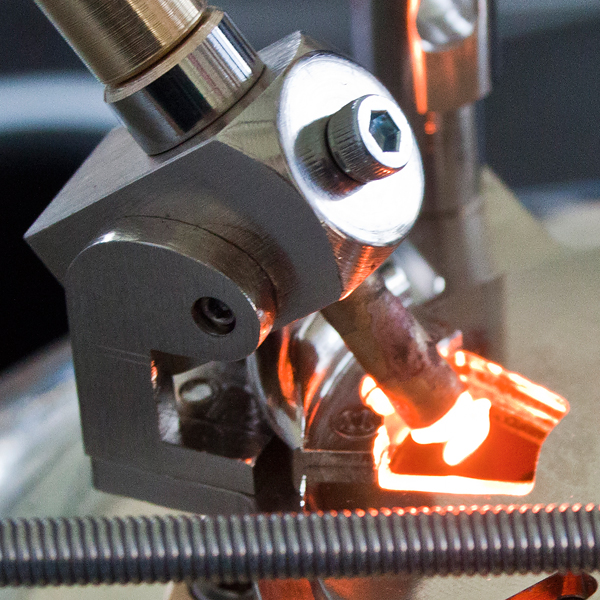

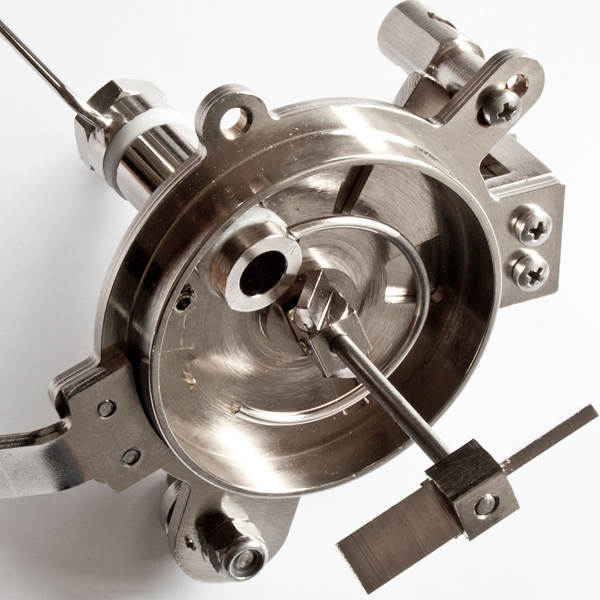

The sample is heated and stirred at specified rates, using one of three defined procedures (A, B, or C). An ignition source is directed into the test cup at regular intervals with simultaneous interruption of the stirring, until a flash is detected.

ASTM D93 procedures A, B, C - ASTM D3941 - ASTM E502

DIN EN 22719

IP 34

ISO 2719